Why does the printing technology matter?

You might think: “As long as it gets printed, I’m good.” But the technology you choose impacts quality, strength, detail, and cost. Knowing what you need – and what’s available – can save you time, money, and frustration.

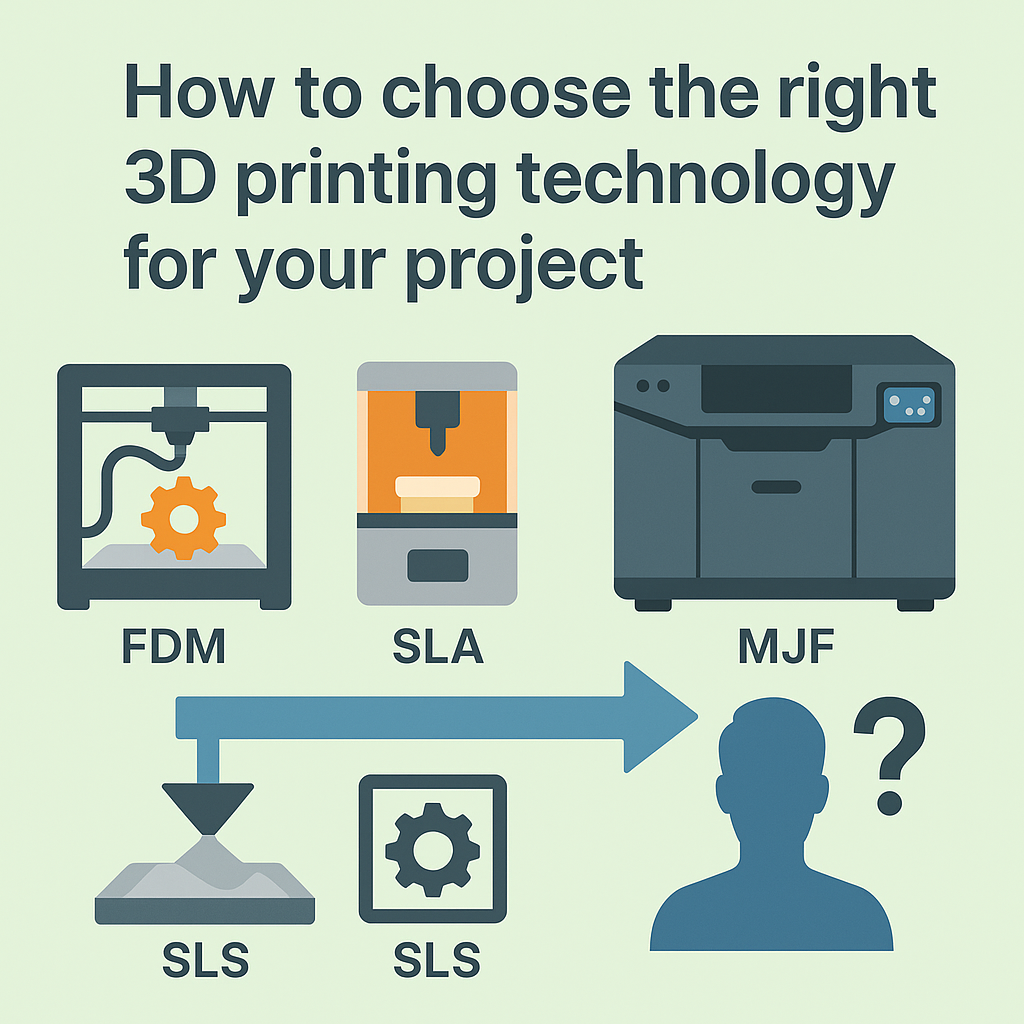

Overview of common 3D printing technologies

FDM (Fused Deposition Modeling)

The most common and affordable method. Thermoplastic filament is extruded layer by layer. We typically use PLA, PETG, ASA, PC or PA (with carbon fiber when needed).

- Pros: Low cost, fast production, solid strength

- Cons: Visible layer lines, limited precision, not ideal for small details

SLA (Stereolithography)

Liquid resin is cured with UV light, producing high-detail models with smooth surfaces.

- Pros: Excellent detail, perfect for miniatures and jewelry

- Cons: Fragile parts, higher cost, requires post-processing

SLS (Selective Laser Sintering)

Powdered material (usually nylon) is sintered layer by layer using a laser. No supports needed, and the parts are very strong.

- Pros: High strength, no supports, ideal for functional parts

- Cons: Expensive, industrial-grade equipment, longer lead times

MJF (Multi Jet Fusion)

An advanced process similar to SLS that delivers even better strength and accuracy.

- Pros: Excellent mechanical properties, smooth and consistent finish

- Cons: Only available through specialized services, higher price point

Which technology fits your project?

- Prototypes and basic technical parts: FDM

- Design models and miniatures: SLA

- Functional mechanical parts: SLS or MJF

- Outdoor use: FDM with ASA or PC for UV and heat resistance

Professional service vs. home printing

Home FDM printers can do a lot – but when it comes to precision, multi-color prints, large formats or demanding materials, it’s worth working with a professional 3D printing service.

At László 3D, we’ll help you choose the right technology, material and model optimization. Try our 3D print calculator – and get an instant estimate for your idea.

Conclusion

Each technology has its pros and cons. The key to success is knowing what you expect from the print – and asking the experts if you’re not sure. We’ll gladly help you find the best solution for your project.