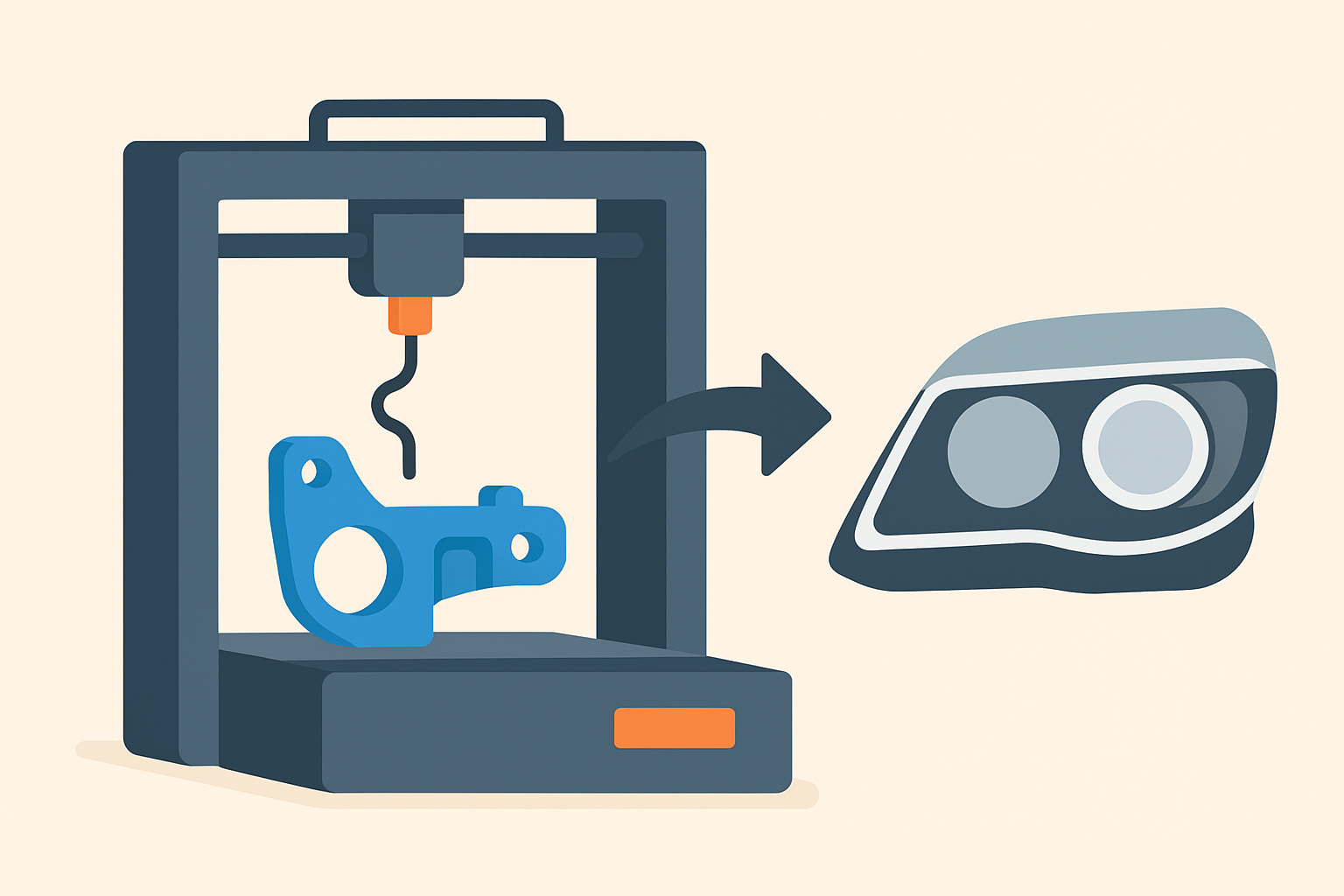

Upgrading a stock headlight to bi-xenon isn’t easy — especially when no factory part exists. That’s exactly what our client needed: a custom bracket to install a bi-xenon projector into a Škoda Octavia II headlight originally designed for xenon.

The challenge: precise alignment and durable mount

The client provided detailed requirements. The part had to:

- align the projector with the original reflector and shield

- maintain optical axis and cutoff shape

- withstand heat and vibration inside the headlight

We designed the bracket in Fusion 360 based on these constraints — entirely from scratch, with no existing part to copy.

Material selection: polycarbonate for reliability

To ensure both thermal and mechanical stability, we chose polycarbonate (PC):

- resistant to temperatures up to 110 °C

- rigid and dimensionally stable

- vibration-resistant in real-world use

Thanks to 0.16 mm layers and fine-tuned settings, the surface was smooth and ready to use with no post-processing.

Installation and testing

The part was test-fitted directly in the headlight assembly. Everything aligned perfectly on the first try, and the projector was mounted securely. The beam remained sharp and properly shaped.

Outcome and impact

The client successfully completed a clean bi-xenon retrofit using a custom part that doesn’t exist anywhere else. And because the CAD model is saved, identical parts can be produced anytime.

Modeling time: approx. 3 hours

Printing time: 2 hours

Planning a similar retrofit?

We can help. Whether it’s a bracket, cover, or something more complex, we’ll design and print the exact part you need. Get a quote or contact us directly.